EQUIPMENT

CNC Milling and Turning Equipment

14 Okuma MX55VAE Vertical Machining Centers

One equipped with a Nikken fourth axis indexer and tailstock. Table travel (20″ X 42″ X 20″)

4 Okuma LB15 CNC Lathes

One equipped with an SMW bar feeder, and parts catcher capable of feeding 2-3/4″ bar stock; With The second turning center has an 8″ chuck with a 1-3/4″ thru hole

1 Okuma LB15II/1000

Big bore spindle (including 10″ chuck) LBS super hydrobar 2.5″ capacity, and 37″ between centers

1 Okuma MB-4000H-CNC Horizontal Machining Center with a 64 tool ATC package

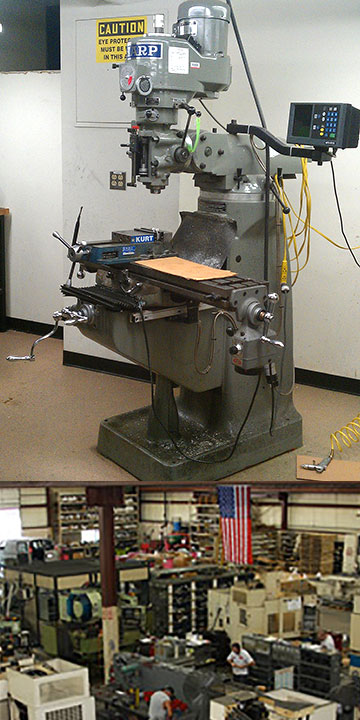

Milling, Drilling and Boring

2 Alliant Vertical Milling Machines

48″ X-Axis travel equipped with accurate digital readouts on both X and Y axis; Kurt angle vise with 1 Cincinnati Bickford, Radial Drill 5″

Spindle 15 HP 60″ Swing

1 Rockwell, Multiple Spindle Drill Press

3 Flexarm, Tapping Machines

Full line of ratchet collet for production or short run tapping requirements

1 DEV-LIEG JIG MILL 4K72

Turning

2 Monarch, EE Tool Room Type Lathes

Both equipped with digital readouts on X and Y axis, 8″ chucks and tailstocks

1 Monarch, CU Lathe

Equipped with a 16″ chuck and 18″ 4 Jaw Chuck Both X and Z-axis digital readouts, steady rest and tailstock 20″ swing and 96″ center distance threading capabilities 1 Monarch 614 Engine Lathe 20″ Swing 72″ Centers

1 Hardinge, Turret Lathe

Equipped with a bar feeder and 5C Collet Spindle

Welding Equipment

1 Hobart Beta-Meg 250 Wire Feeder

1 Miller Syncrowave 250 CC-AC/DC Welder (Wire, Tig, Stick Welding – we could probably even weld pencils if it became necessary)

Grinding

Kent, Surface Grinder

14″ X 48″ Table equipped with digital readouts on both Y and Z axis

1 Cincinnati, O.D. Grinder 4-1/2″ swing X 20″ travel

1 Harig, Toolroom Surface Grinder

6″ X 12″ Table

1 Enco, Pedestal Grinder

1 W Dual Drum Buffing Machine

Miscellaneous

2 Amada Cutoff Saws Capable of .002 tolerance on cutoff lengths. Fully automated

1 Wellsaw Model 118, Horizontal Cutoff Bandsaw

1 Vertical Bandsaw

1 Everett 14″ Cutoff Saw

Angle vice and work stop, and bar support, this machine will saw hardened material

1 Enerpac, 10 Ton Hydraulic Press used for broaching

1 Leroi, 30HP Air Compressor

7 Dynafile, Air Driven Belt Deburring Tools

1 Yale 3 Ton Forklift

1 Daewoo 5 Ton Forklift

Inspection and Gauging Equipment

1 Brown & Sharp Microv AL 2+ CMM

1 Starret, Granite Surface Plate

1 Full Range of Ring Gages

1 Full Range of Thread Rings and Plugs, Both Metric and English

1 Sunnen Dial Bore Gages, Range .400-6.00 Including set Masters

1 Snap Gages, Knife Micrometers, Full Range of Outside Micrometers Up To and Including 16″

1 38″ and 26″ Calipers

1 Height Gage, Light Gage, Air Gages

1 Lectroetch, Etching Machine

1 Misaw Sieki Hardness Checker, Checks Rockwell ‘C’ and Superficial Hardness